Shanghai, China

Showing heart

The city’s expanding metro network and a community-managed housing development show how modernizing can epitomize care, attention, and doing what’s right for the people who use these facilities every day.

Modernizing the metro

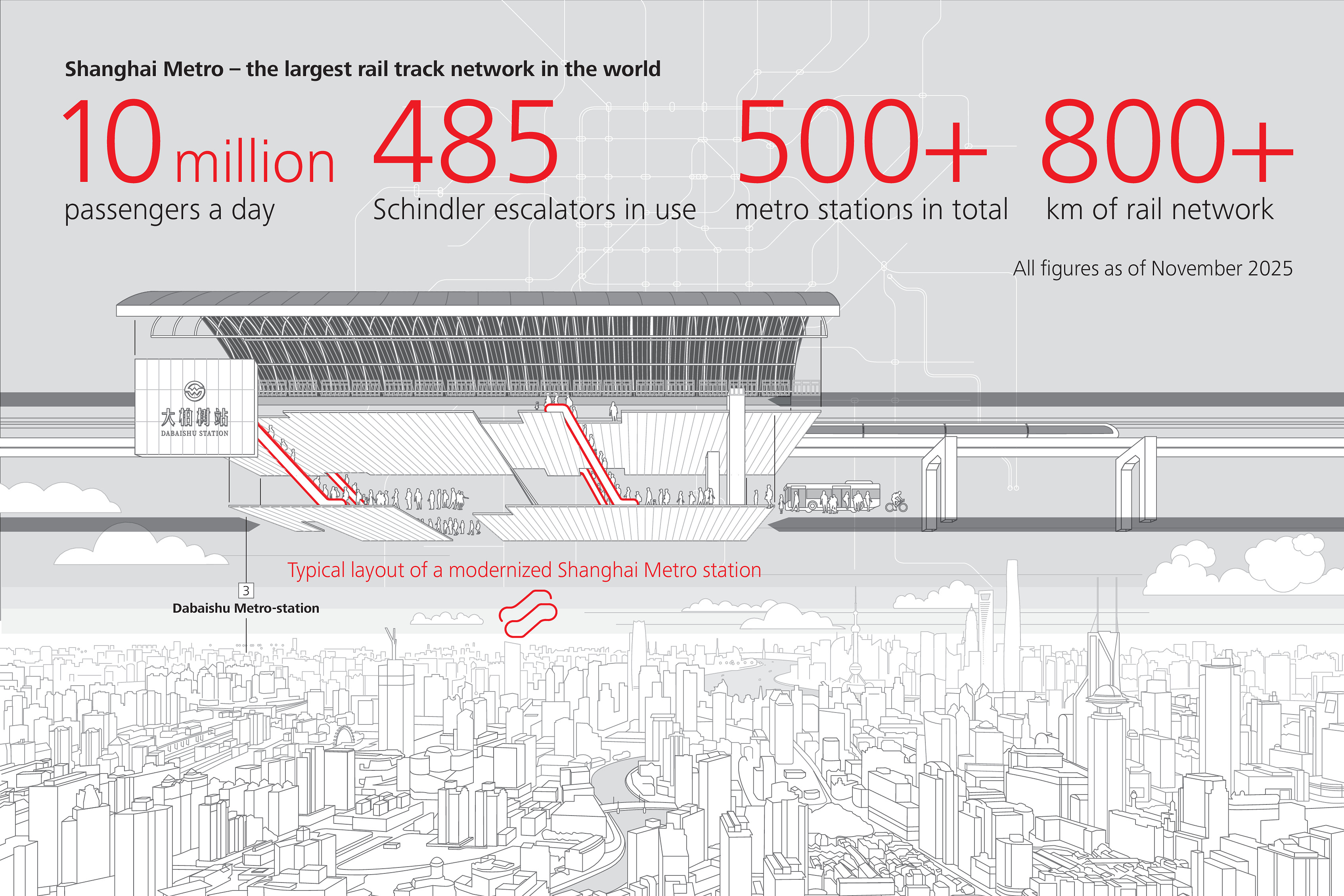

It’s hard to imagine how Shanghai would operate without its metro system. It’s one of the busiest in the world, with over 10 million people using its interconnected lines to travel through the city every day.

“I take the subway every day to work. It’s very convenient,” says Yichao Shi, Schindler technician, as he parks his electric scooter outside Dabaishu metro station on Line 3. “The metro covers so much of the city. It’s much easier to travel by public transport than it used to be, and scooters are great for the bits in between,” he adds with a smile.

Today, Yichao is here to do routine checks on the station’s six escalators. His team in Shanghai recently modernized 191 escalators across multiple metro stations along Lines 3 and 6 – which opened in 2000 and 2007, respectively.

Since Lines 3 and 6 first opened, Shanghai has undergone massive expansion. The metro system alone has more than tripled in length, and, with the sharp increase in passenger numbers, it’s important that the older stations stay up to date with modern equipment.

After nearly two decades of daily high-volume passenger traffic, the escalators were in need of modernization. “The escalators in these stations have to handle a huge amount of daily traffic,” says Ke Yang, general manager, Schindler Shanghai branch. “They’re essential for keeping passengers moving smoothly and preventing bottlenecks during peak hours. The main challenge was to do the renovation work without disrupting the stations’ operations and the surrounding environment.”

To make this possible, the modernization team used an innovative solution: Schindler INTRUSS®. Instead of removing the entire unit, the team left the existing escalator truss in place. The old parts were removed, the truss cleaned and treated with a specialized derusting coating to prevent corrosion, and then new components were fitted inside – meaning no structural redesign or lengthy delays were needed. Out with the old, in with the new.

“We can modernize different types of units this way – not just Schindler escalators, but also third-party brands,” explains Yini Shi, senior engineer and Schindler INTRUSS® expert. While it sounds straightforward, it requires, among other things, a thorough knowledge of escalator components and installation methods.

The team conducted thorough on-site surveys of the escalators before installation began. This detailed planning, combined with Schindler’s expert installation methodology, provided a structured step-by-step approach that ensured precision, safety, and optimal performance.

“Using this method optimizes installation time, as on-site modifications are kept to a minimum, so we get the escalators back up and running sooner,” says Yini.

Then, to further minimize disruption on-site, all construction work was done overnight after the last trains had left the stations.

Schindler hasn’t simply replaced the escalators – there’s been a significant upgrade in how they operate as well. The escalators are now safer and more energy-efficient.

The escalators are now fitted with cloud connectivity, enabling remote monitoring via the Technical Operations Center (TOC), thus enhancing reliability and reducing maintenance-related disruptions that could cause passenger congestion and delays.

“Overall, the new escalators run smoother and are more efficient than before,” says Yichao Shi. “The upgrades have improved the commuting experience, making it easier for hundreds of thousands of people to get to where they need to go,” he adds, as he boards a train to continue his work at the next station along the line.

An expanding service

Across town in Pudong, Shanghai’s financial district, it’s not only the skyscrapers above ground that catch the eye. The underground stations of Shanghai Metro’s Line 14 have also been turning heads.

“The stations are quite stunning,” says Ke Yang, general manager of Schindler Shanghai branch. With unique designs and vast arrays of LEDs – that change color and pulsate along the walls and ceilings – the stations along Line 14 have become attractions in their own right. “Our escalators play a crucial role in keeping the stations functioning and operational,” adds Ke.

When the line opened at the end of 2021 to help connect the east with the west of the city, Schindler’s team in Shanghai installed 237 Schindler 9700 escalators. Ranging in height from 4 to 15 meters, they’re spread over 14 metro stations along the Pudong section of Line 14, from Lujiazui to Guiqiao Road.

“Now, we maintain hundreds of escalators across Lines 3, 5, 6, 14, and the Shanghai Maglev (a high-speed magnetic levitation train that connects Shanghai Pudong International Airport to the city’s Longyang Road metro station),” says Qingshou Zhang, senior manager at the Shanghai Technical Operations Center (TOC). “And they’re all connected and monitored via our TOC.”

When it comes to infrastructure projects like the Shanghai Metro, connected units provide the teams with valuable real-time information that allows them to provide a more complete service – one that benefits both customers and end users.

The ability to monitor these units has transformed maintenance operations. All installations in China must undergo maintenance checks every 15 days.

“Remote monitoring means we know what’s going on even before we get to a unit,” explains Liang Xu, Existing Installations manager. “It saves us so much time, as we know which parts and tools are required beforehand.” In addition to reducing callout trips, it also helps keep downtime to a minimum – this way, the stations can continue to turn heads for all the right reasons.

Shanghai born and bred

Liang Xu, Existing Installations manager, talks about how Shanghai has changed since his childhood.

When did you join Schindler?

After graduating from technical school. Back in the 1980s, Schindler was one of only four Sino-foreign joint ventures. As a young technician, I was given a position of responsibility and, at the same time, the chance to work on a lot of different projects. I’ve stayed with Schindler ever since, always in Shanghai. It’s been over 35 years now.

How has Shanghai changed as a city during that time?

A lot. When people think of Shanghai now, they usually picture the view across the river from the Bund, Shanghai’s prominent waterfront promenade, and think of a city full of densely packed skyscrapers. But when I was growing up, there were no high-rise buildings in Pudong (Shanghai’s financial district).

I was born in the 1970s, so I’ve experienced the era of reform and opening up. The city has transformed into a globally important financial metropolis.

How would you describe the cooperation with Shanghai Metro?

When I started at Schindler, the city didn’t have a metro system. But since then, it’s grown to cover every corner of Shanghai.

We’ve worked with the Shanghai Metro since 1999, and we’ve always had a good partnership with them. I think this is one of the reasons we were chosen for the major overhauls of the escalators in the stations along Line 3 and Line 6.

What is the biggest challenge your team faces now? And how do you deal with it?

The biggest pressure comes from on-site execution. Shanghai Metro is a major public transportation system. Many people rely on it, so we have to make sure that escalators keep working. We always have technicians ready to deal with any maintenance required.

Remote monitoring has greatly helped our work. Previously, diagnosing issues required staff to go on-site and check error logs or use multimeters to test switches. Now, our staff receive notifications and can often identify the problem before arriving on-site.

We also receive “minor issue” alerts for things that haven’t caused a shutdown but could potentially become a problem. This allows us to perform preventive maintenance, much like regular health check-ups.

This approach benefits all our equipment and helps frontline staff address issues more effectively.

For example, one evening we detected a potential issue at a station, which could have had a significant impact if the escalator had stopped. We immediately contacted the factory and had the replacement part delivered overnight. The escalator was back in full operation by 5:30 a.m. the next day. This teamwork between our on-site staff and our factory workers minimized the impact on customers and on hundreds of thousands of people using the metro every day.

“Remote monitoring means we know what is going on even before we get to a unit.”

Liang Xu, Existing Installations manager for the metro project in Shanghai

Residential renovations

With a population of over 24 million, Shanghai is a city that a lot of people call home. Countless residential developments sit alongside the modern high-rise buildings the city is famous for – offering residents easy access to restaurants, commercial hubs, and transportation links in every direction.

One such complex is Yipin New Building Garden, in the city’s central Hongkou District. The gated community is made up of 24 16-story buildings, home to 698 apartments. Step inside the gates, and ginkgo trees line the peaceful paths between buildings while cats sun themselves on the entrance steps – it’s easy to forget that you’re so close to the center of one of the world’s biggest cities.

But creating a safe and warm home means more than a tranquil setting. It requires infrastructure that works seamlessly, day in and day out.

In March 2024, a working group composed of property management, the owners’ committee, and resident representatives decided it was time to modernize the elevators that had been installed when the complex opened back in 2003.

“There were lots of small problems with the previous elevators and after 20 years, those issues just kept increasing,” explains Youguo Wang, an owner and community consultant. “The elevators are very important to our daily lives, especially for those who live higher up.”

“They had started to reach the end of their life cycle,” adds Wen Zhu, the appointed representative for Building 6. “Even though our elevator was still working quite well, we didn’t want to wait for it to break down before replacing it.”

The group’s decision to take action was helped by an announcement that the Chinese government would provide subsidies for elevator modernizations in the form of national ultra-long-term government bonds.

“This new policy really got the owners thinking,” says Sherry Sun, vice president of Modernization at Schindler China. “It was then our role to prove to them that we were the right partners for the job.” A key part of this was explaining the value of being able to deliver a one-stop service to the customer – from manufacturing the parts, to installation and maintenance.

“It made me feel secure and comfortable that we’d made the right decision,” says Wen Zhu. “Two of the other companies we spoke to use third-party services after installations, but Schindler takes care of everything themselves.”

Haibing Xiao, Schindler project manager at Yipin New Building Garden, explains that the goal was to provide modern, functional, and efficient elevators that would have a positive impact on residents’ lives. In total, the team modernized 23 units – one per building – replacing the main ropes, machines, and controllers to ensure they all meet modern safety standards.

“Throughout the project, the tenants were still living on-site,” says Haibing. “So, we had to ensure there was a safe environment at all times and be aware of the noise we were making.”

Loud construction was avoided during early mornings and evenings, and core components were pre-assembled to reduce on-site work. Additionally, to keep the buildings clean, construction waste was sealed in bags and removed regularly.

With each block having only one elevator, keeping everyone informed about progress and timing – and then delivering on schedule – was critical throughout the project.

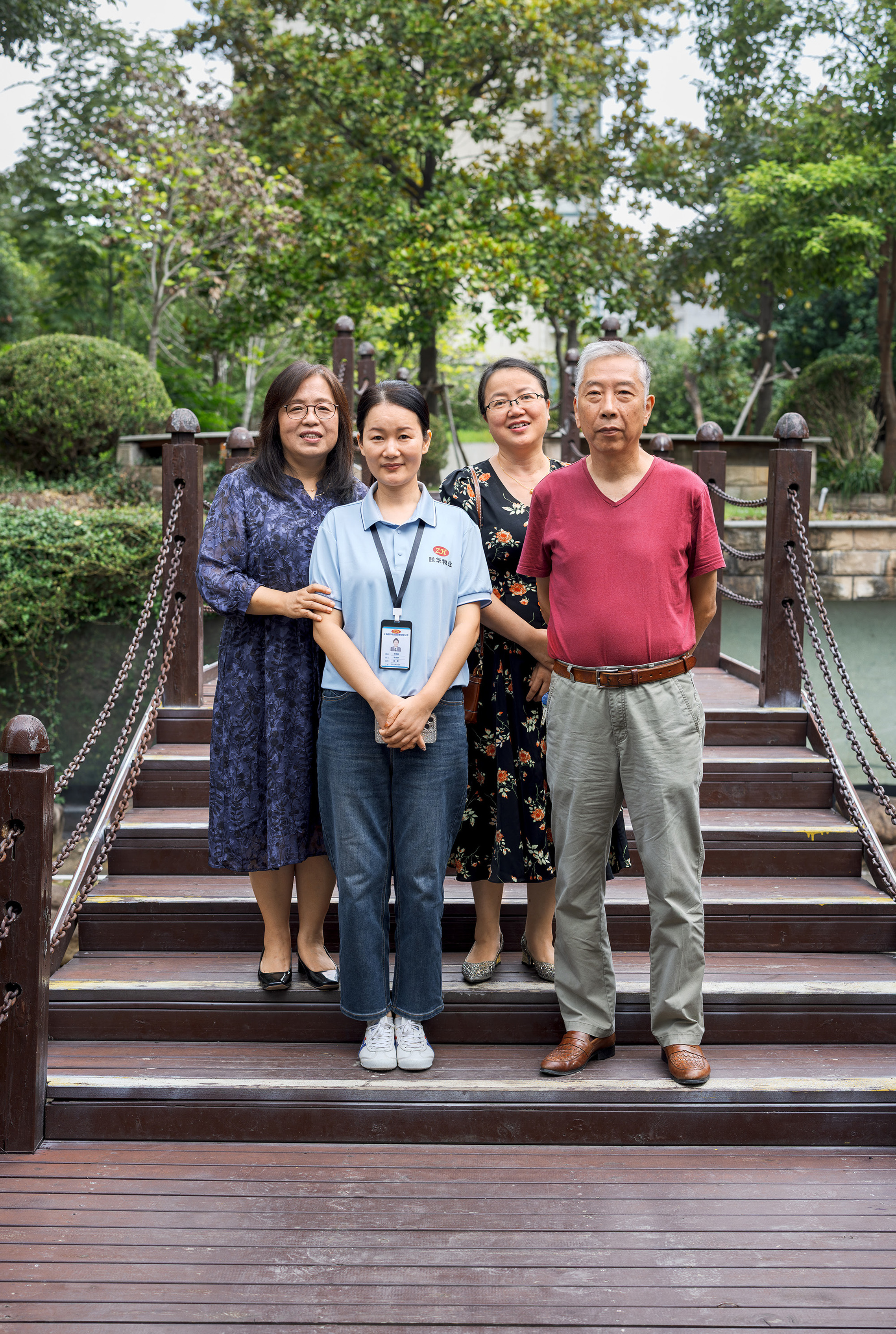

“There was some impact to the residents’ daily lives, but the process and schedule was well communicated so people knew what was going on and what to expect,” explains Lili Yin, property manager. “The Schindler team were very professional and listened to any concerns that were raised during the installation of each elevator.”

The new elevators now provide a smooth and comfortable ride, and their speed has almost doubled. Inside, the mirrors make the elevators feel bigger and brighter than before, and the handrails are convenient for the older residents.

“We really like these features,” says Yingfen Hu. “They not only improve the quality of life for the people living here, but they also help maintain property value and lower running costs, ensuring our homes are appropriately equipped for the future.”