San Francisco, USA

Flow State

San Francisco is a city in transition. The Big Tech capital is being prepared for the future – and that includes people mobility. Schindler is at the heart of things, modernizing the escalators and elevators of various flagship projects.

Indispensable

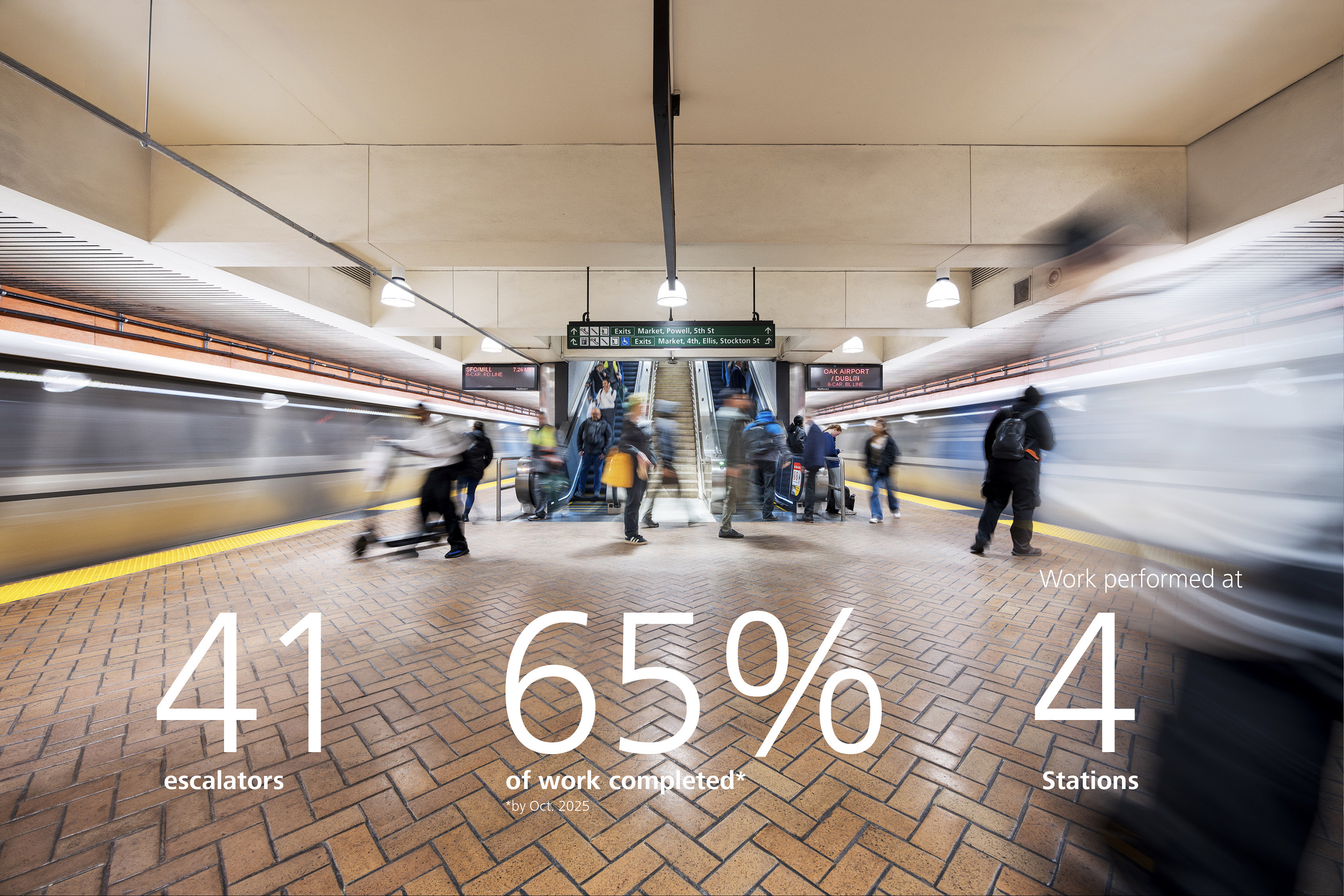

The Bay Area Rapid Transit (BART) system is an essential part of public transportation in the Greater San Francisco area. In four high-traffic stations in the city center, the Schindler team is modernizing 41 escalators – while commuters continue their daily lives undisturbed.

Calm and focused, Virol Providence works on the inner mechanics of a Schindler 9700 escalator at Montgomery Street metro station on the BART network, as thousands of commuters rush past toward the trains or out onto the street.

BART has been an integral part of the Bay Area since 1973, connecting the San Francisco Peninsula with major cities in the East Bay and South Bay, including Oakland and San José. Spanning 211 kilometers, BART is an essential transit link for commuters going to work, tourists visiting landmarks, and students heading to world-renowned universities.

Since 2020, Schindler teams in California have played a key role in this massive underground modernization project, retrofitting 41 escalators across four BART stations – Embarcadero, Montgomery Street, Powell Street, and Civic Center. Located beneath the legendary Market Street in downtown San Francisco, these are the busiest of all 48 BART stations in terms of passenger volume.

Virol Providence is one of the team leaders on the project. When he’s not working on the equipment, he oversees logistics and site organization. He’s been with Schindler since 1999 and offers a seasoned perspective: “The hardest part of modernizing the escalators is the tight space. We’re wiring everything in extremely confined areas. I enjoy working with electronics the most, but it’s challenging. What we’re doing here isn’t plug and play.”

Beyond the escalators themselves, the team handles critical support tasks – like setting up barriers to ensure constant safety in the stations.

Twenty-three escalators lead from street level down to the concourse level. From there, passengers descend via another 18 escalators to the platforms. Of these 41 units, the teams are modernizing 23 using the proprietary Schindler INTRUSS® method, which retains the existing structural frame (“truss”), while replacing worn-out components with new, modern parts – steps, drives, controls, safety and comfort features. After the upgrade, which is expected to be completed by 2027, it would take a trained eye to distinguish these escalators from brand-new ones – thanks to their improved safety, performance and energy efficiency features, and modern appearance.

Another eight escalators have been fully replaced, and nine brand-new ones have been installed. The Schindler 9700 model selected for these upgrades was engineered for durability and long-term performance, and worldwide, it has proven itself in high-traffic public areas and even against vandalism.

For Schindler’s technicians, the BART project feels deeply personal. They’re all from the Bay Area and have used the metro since childhood. “BART has always been here – it’s part of the Bay Area,” service technician Matthew Wyder says enthusiastically: “I don’t have to explain to my family and friends what I’m working on. I just say ‘BART,’ and they get it.”

His colleague Andrew Fowler has also forged a personal connection with the metro network: “As a child, I used to ride this exact escalator. Now I’m here making sure it works perfectly.”

Matthew Goepel is Schindler project manager for BART. One of his key challenges is coordinating teams across modernization, new installations, service, and repairs in an environment that never sleeps. Metro passengers come and go all week long, including during weekends. “We try to be as invisible and quiet as possible. Fortunately, each of the four stations has four or five entrances, and of course, we don’t renovate all the escalators at once. And we aim to communicate as much as possible to minimize complaints.”

Logistics have also proved challenging at times – given their sheer size and weight, the escalators and some of the replacement parts had to be hoisted underground from the street – a complex operation made more difficult by the high pedestrian traffic in the stations and the heavy vehicle traffic on Market Street above.

But it’s all been worth the effort, according to Matthew Goepel who is confident in the value that the work brings: “Our product is the best on the market. For example, if no one is using the Schindler 9700 escalator, it automatically slows down to save energy. The escalators at BART didn’t have that capability before. We had to advocate for this sustainability upgrade, but now the client is happy with it.”

Schindler’s San Francisco branch is located on the east side of the Bay, in San Leandro. Under the leadership of general manager Geoffrey Hussey, it services the entire Bay Area – a region stretching 650 kilometers to the north, 240 kilometers to the south, and 150 kilometers east and west.

“In the Bay Area, Schindler is perceived as an innovative engineering company,” says Geoffrey proudly.

This reputation stems from its widely adopted Schindler PORT destination management system and its OEO (Occupant Evacuation Operation) elevators. During fires or emergencies, these smart elevators safely evacuate residents from high-rise buildings – up to 50% faster than stairs alone, and in a far safer way for less-mobile occupants. An OEO elevator often eliminates the need for a separate emergency stairwell, freeing up space for more apartments in residential buildings or office space in commercial towers. Meta’s high-rise building on Howard Street in downtown San Francisco uses this technology.

“BART is part of my life. I used it to go to school, and now I ride it to work every day.”

Robert Johnson Escalator Technician

“A smooth partnership”

Mark Dana, project manager at the Office of Infrastructure Delivery at BART, reflects on their collaboration with Schindler and the importance of the metro to the San Francisco Bay Area.

What makes the Market Street project partnership so special?

From the very beginning, it’s been a prime example of cooperative teamwork. Schindler, BART management, and the on-site teams planned the project together and worked in close alignment throughout. This approach has enabled us to identify and resolve potential issues early and respond quickly to unforeseen situations. Communication is open, honest, direct, and professional – with no hidden agendas.

How important is the BART public transport system for the San Francisco Bay Area?

BART is the most important transportation system for commuters and visitors in the Bay Area. It also helps reduce car traffic, air pollution, and energy consumption.

What role does sustainability play for BART?

Sustainability is a top priority for us. We wanted escalators with energy-saving regenerative drives and eco-mode functionalities – something Schindler could provide. We also place real value on having multiple units with interchangeable parts, as it simplifies procurement and makes replacements faster and more efficient.

How many people use the metro?

We’re currently approaching the ridership levels we had before the Covid-19 pandemic – at that time, over 400 000 passengers used the metro daily on average.

How important is fast and reliable access to your stations via escalators?

Extremely. We’re proud to offer a safe, clean, and reliable service. This has earned us a good reputation and the public’s trust.

Why did you entrust Schindler with this project?

We selected Schindler through a tendering process because the company is responsible and responsive, and we were very satisfied with our existing collaboration.

“Communication is open, honest, direct, and professional – with no hidden agendas.”

“I’m very impressed by the professionalism and collaborative spirit of all the employees.”

Mark Dana, Project Manager, Office of Infrastructure Delivery at BART

Upside down

In downtown San Francisco, the Schindler team is taking on a rare project: at 201 Mission Street, they’re extending nine elevators – not upward, but downward. The reason for this unique project? An earthquake.

It’s an unusual sight. In the elevator shaft, the guide rails end far above the heads of the technicians, who are busy lowering the elevator shafts by one floor, extending the vertical rails and hoist ropes, connecting cable bundles, positioning additional crossbeams in the shaft, and creating a new shaft access point. They’re also integrating a new version of Schindler PORT and replacing and adapting all the control features.

“If it sounds like a huge operation, that’s because it is one!” says Jeffrey Rooney, foreman at 201 Mission Street. An experienced technician with specialist electronics training, Jeffrey was brought to San Francisco from nearby San José by the superintendent in charge of 201 Mission Street, Heath Myers. It was the right decision.” Jeffrey and his team are handling this modernization task with confidence and skill,” says Heath.

The project team includes technicians from the Bay Area, Texas, and Hawaii. Reese Littleton, from Houston, speaks on behalf of his colleagues. “This project is truly unique. I’ve never done anything like it – we’re turning everything upside down. And I’m learning something new every day.”

There’s no blueprint for a retrofit like this. Jeffrey and his team are testing some of the technical solutions for the very first time. The walls of their makeshift workshop are covered with sketches and schematic drawings, and tool prototypes are stacked on the shelves. “Sometimes I wake up at two in the morning with a new idea,” Jeffrey says with a smile.

The reason for this extraordinary project is as surprising as it is logical. The 127-meter-tall Providian Financial Building, then called the Pacific Gateway Building, was completed in 1981, and was flanked by the double-deck Embarcadero Freeway, which divided the city. Visitors entered the building from this elevated highway, stepping into the lobby located one level up from the first floor. The low-rise elevators served the first 18 floors, while the high-rise elevators served floors 19–30.

That was until October 17, 1989, when 15 seconds changed everything. The Loma Prieta earthquake destroyed the Embarcadero Freeway, and the city demolished it entirely in 1991. Suddenly, the entrance to 201 Mission Street was at street level – without an elevator. Solutions were discussed and discarded until a temporary solution was agreed upon – two escalators were installed to take people up to the lobby. Eventually the lobby was rebuilt on the floor below and the elevators extended accordingly.

The technicians are now tackling the tricky task one elevator at a time. Work on all nine elevators is due to be completed in 2026. “In my 30 years in the elevator industry, I’ve never heard of such an intervention in a building this tall,” says Jeffrey. “And my father and my uncles, who were all elevator mechanics, have never mentioned anything like this either. I’m really excited about completing this one-of-a-kind challenge.”

Working in the wings

At San Francisco International Airport, it’s not just the airplanes that keep people moving. Schindler mechanics on the ground service 77 elevators around the clock so that travelers can take off.

George Ortiz has just finished servicing an elevator in Parking Garage B, and is now back in his electric van, heading to the United Airlines hangar to take care of a freight elevator. Overhead, a jet roars in for landing, but he doesn’t flinch – it’s the soundtrack to his work.

San Francisco International Airport boasts a spectacular location on the shores of the Bay, around 20 kilometers from downtown. It is well-connected to the city center via the iconic BART metro. Each year, almost 50 million passengers travel through the airport, making it one of the 12 largest and busiest in the U.S.

Schindler’s service crews maintain not only Schindler elevators, but also some produced by other companies. Whatever the make, safety is always top of mind for the teams. It’s a mantra George lives by. “Elevator users must feel 100% safe. That’s my goal. That’s why I do maintenance, service, and any necessary repairs. We oil, grease, check cables, and make sure the doors close properly.”

George has been in the elevator industry for almost twelve years and has worked for Schindler since fall 2024. “I like Schindler because it takes such good care of its people. That really sets it apart from many others.” And George knows what he’s talking about. When the father of four had a serious health issue last year, he received an outpouring of support from Schindler. Geoffrey Hussey, general manager at the San Francisco branch, called regularly to check in with George’s wife.

George’s colleague, Brian Bilbao, is a single father to an 11-year-old daughter who has also experienced the caring side of the company during tough times. “I feel a deep connection to Schindler,” he says. “It’s like a big family. We look out for each other.”

That level of care extends to the elevators at the airport. The service technicians work together to maintain the elevators and handle any issues that arise. Among the 77 units are 12 older but fully functional Westinghouse models, which require specialized knowledge – knowledge that Brian has developed over more than a decade in the elevator business.

Meanwhile, behind the scenes, associate project manager Lindsay Ruhland takes charge of crew organization to ensure seamless coverage and exceptional service during the airport’s operating hours – which is 24/7. “Our clients tell us that our employees communicate very well, respond quickly to requests, and solve problems as they arise,” she says with a note of pride in her voice.

The airport is an important travel hub for San Franciscans. That’s one of the reasons why George Ortiz is so happy to hear positive feedback from clients. “Our customers feel that Schindler is well run. We’re transparent with them, and that’s why they trust us. They always say they’re happy with us,” he explains with a broad smile.