São Paulo, Brazil

First Ladies

At Schindler Brazil, most major projects are managed by women. This was also the case for JK Square in São Paulo, where a further influx of support arrived from Switzerland to assist with the two-tower project.

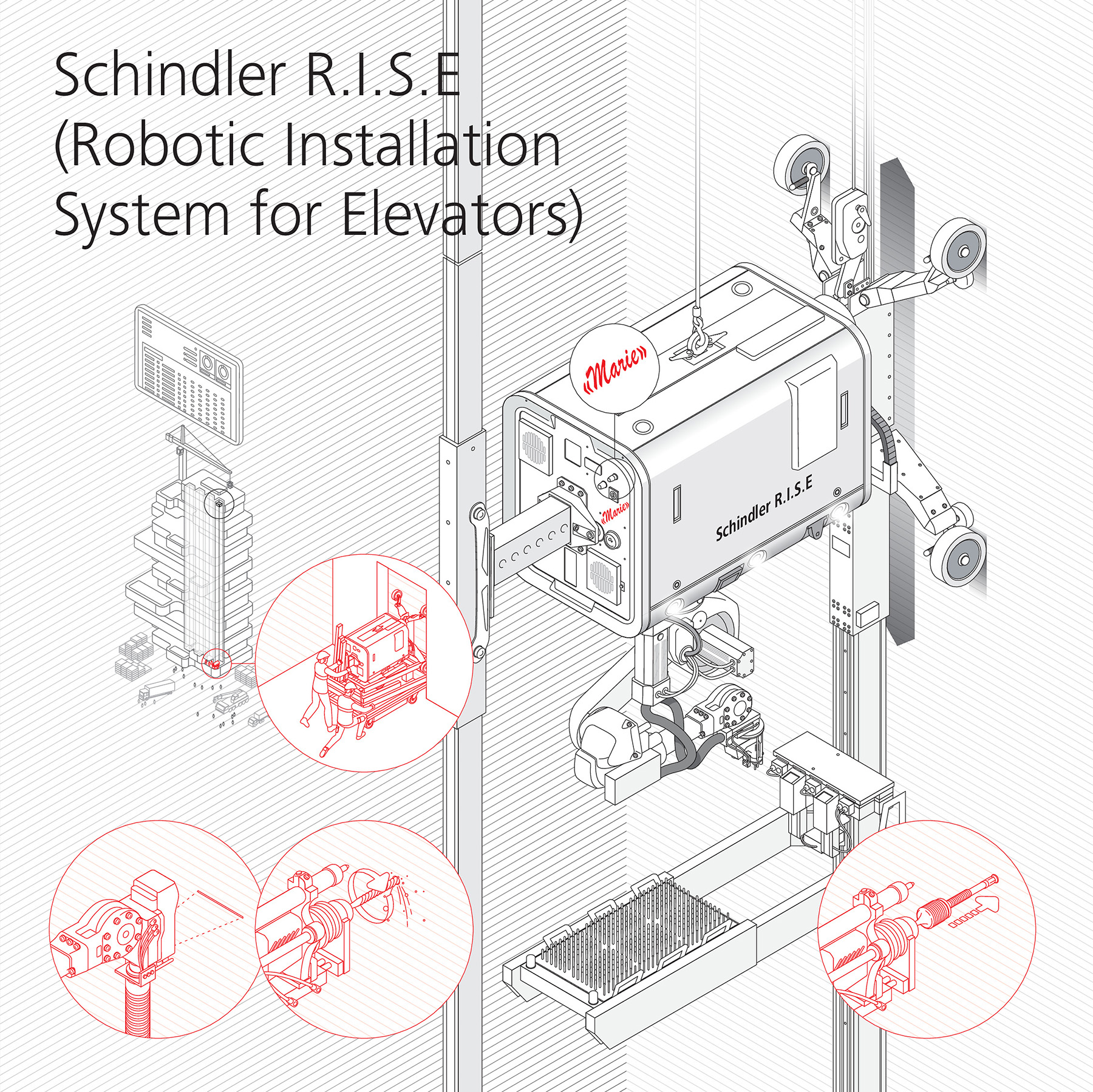

Marie spent six weeks in transit, crossing the Atlantic from Ebikon in Switzerland to São Paulo in Brazil, where it had to wait at customs. Marie is a 900-kg robot, a highly developed technological tool used by Schindler for elevator installation. The system is called Schindler R.I.S.E (Robotic Installation System for Elevators). Marie is one of five robots currently touring the world and the first deployed in the Americas. Viktor Wyrsch, trainer at Global Fulfillment, accompanied Marie on the journey in September 2023.

Their destination: the prestigious JK Square project in São Paulo, named in honor of former President Juscelino Kubitschek, founder of the national capital, Brasilia. Engeform is constructing two high-rise buildings in the Itaim Bibi district in São Paulo’s western zone, the larger encompasses 51 residences and 187 hotel rooms on 26 floors; the smaller comprises 20 floors of office space, five sublevels, 12 retail outlets, and a rooftop helicopter pad. With traffic in greater São Paulo exceeding ten million vehicles per day, businesses have devised creative solutions to avoid traffic jams – executives sometimes helicopter to urgent meetings.

Marie was on hand to prepare the installation of four Schindler 7000 elevators, critical to such high-rise buildings. The robot was instructed to scan the shaft structure, conduct measurements, drill holes in the proper locations, then fit anchor bolts to be used in the next installation step. Everything is done automatically, efficiently and with great precision, in a single process without pause.

Giovana Ribeiro Zambrano, one of six major project managers at Schindler Brazil, welcomed Marie and Viktor at JK Square. She supervises the assembly of the prestigious Schindler 7000 elevator series and 14 Schindler 5500 elevators. Giovana coordinates the employees on-site as well as her six-year-old twins at home. How does she do it? According to Giovana, “It’s a balancing act that usually succeeds.” She was thrilled at Marie’s arrival: “The robot makes elevator installation more efficient and means we can work at night.”

At Marie’s debut, Viktor Wyrsch gave instructions to his Brazilian colleagues, who were asked to handle the robot with great care. Predeployment, the robot needs to be adapted to the shaft dimensions. Schindler technicians then push it on its blue carrier up to the shaft and suspend it from a steel cable attached to a massive red hook dangling from the ceiling of the elevator shaft. Marie and the drilling arm slide from the carrier into the shaft and the steel cable grows taut. For a moment, Marie was suspended above the abyss below. The robot climbs up the shaft, placing anchor bolts for rail brackets and doors as it rises. Marie required 28 hours to complete the shaft’s full 96 meters. As with Schindler elevators and escalators, data can be analyzed remotely, and any dimensional deviations can be adjusted.

Viktor Wyrsch has worked at Schindler since 1989. His experience resulted in his early involvement when the Research and Development Center began to develop Schindler R.I.S.E in collaboration with its strategic partners. He comments, “I’m always asked at construction sites about the advantages the robot presents. It takes over repetitive, monotonous, and physically demanding tasks, allowing installation in 130-meter doorless shafts. Not only that; it makes for a safer workplace and installers can move to more interesting tasks.”